Materials:

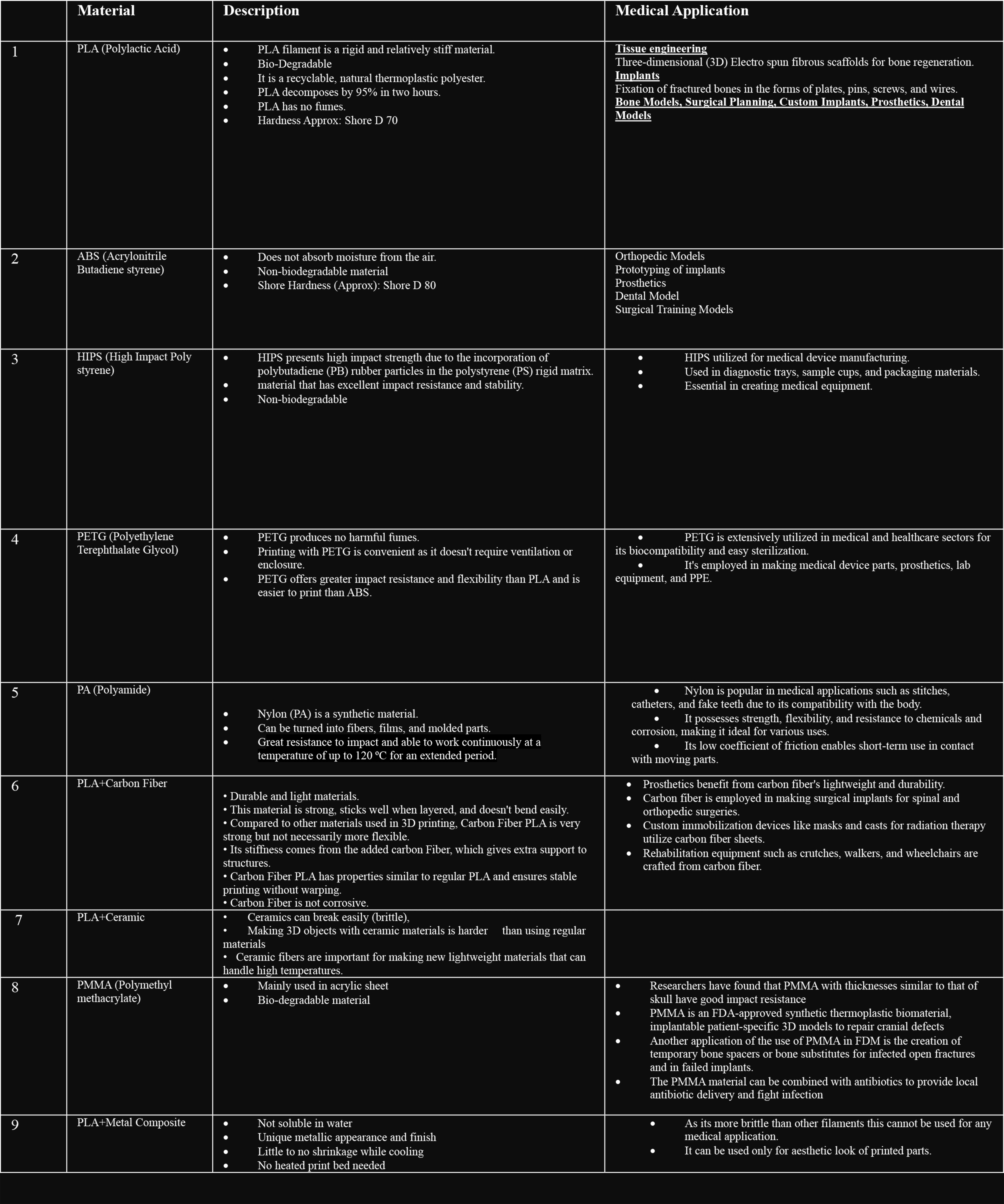

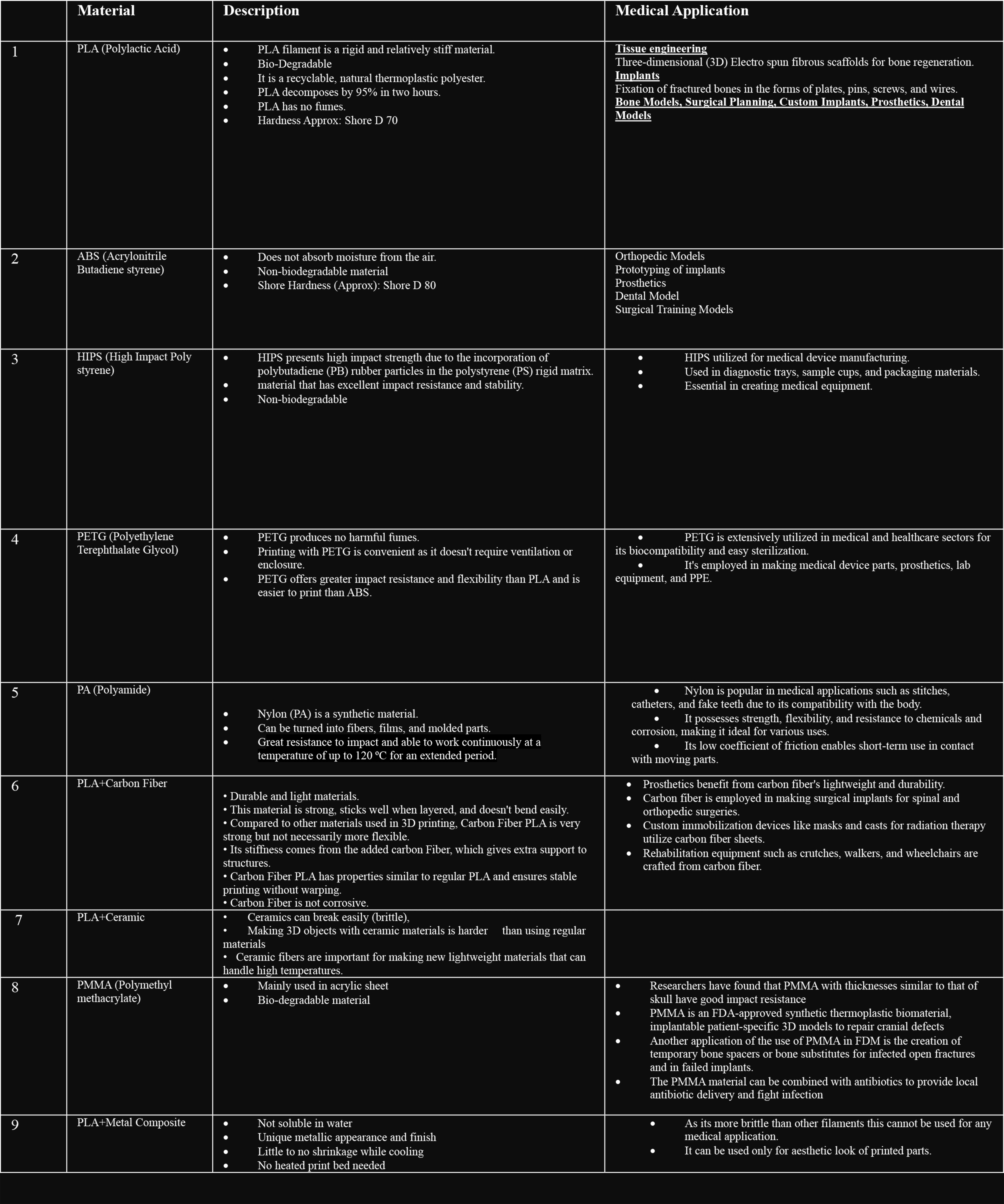

1 PLA: (Polylactic Acid)

2 ABS: (Acrylonitrile Butadiene Styrene)

3 HIPS: (High Impact Polystyrene)

4 PETG: (Polyethylene Terephthalate Glycol)

5 PA (Nylon): polyamide

6 Carbon Fiber (PLA Composed)

7 PMMA: (Polymethyl methacrylate)

8 Ceramic

Materials:

1 PLA: (Polylactic Acid)

2 ABS: (Acrylonitrile Butadiene Styrene)

3 HIPS: (High Impact Polystyrene)

4 PETG: (Polyethylene Terephthalate Glycol)

5 PA (Nylon): polyamide

6 Carbon Fiber (PLA Composed)

7 PMMA: (Polymethyl methacrylate)

8 Ceramic

PLA (Polylactic Acid)

PLA (Polylactic Acid)

PLA is a popular thermoplastic material used in fusion deposition modeling (FDM) that has an extensive range of medical uses owing to its biodegradable characteristics. PLA is a kind of plastic often used in 3D printing, especially in medical, automotive, electronic fields, and medical application. It's good for the environment because it can break down naturally and comes from renewable sources like corn or sugarcane.

PLA is a popular thermoplastic material used in fusion deposition modeling (FDM) that has an extensive range of medical uses owing to its biodegradable characteristics. PLA is a kind of plastic often used in 3D printing, especially in medical, automotive, electronic fields, and medical application. It's good for the environment because it can break down naturally and comes from renewable sources like corn or sugarcane.

ABS (Acrylonitrile Butadiene styrene)

ABS (Acrylonitrile Butadiene Styrene) filament is a thermoplastic polymer, non-biodegradable material. It is a strong and tough plastic used in 3D printing . It doesn't break easily and can handle high temperatures (thermoplastic) during printing. ABS is durable and lighter than PLA, another common 3D printing material. It's also more resistant to impacts. Unlike some materials that only get wet on the surface, ABS absorbs water, but the amount depends on how long it's exposed to the environment .

ABS (Acrylonitrile Butadiene Styrene) filament is a thermoplastic polymer, non-biodegradable material. It is a strong and tough plastic used in 3D printing . It doesn't break easily and can handle high temperatures (thermoplastic) during printing. ABS is durable and lighter than PLA, another common 3D printing material. It's also more resistant to impacts. Unlike some materials that only get wet on the surface, ABS absorbs water, but the amount depends on how long it's exposed to the environment .

It is a 3D biodegradable material, an amorphous thermoplastic material. It's a type of plastic used in things that don't get too hot. People often use it as a dissolvable support for 3D printing. ABS is another, stronger material that can handle higher temperatures and impacts better than HIPS. It's safe to use, so it won't harm people handling it. Just like PVA, HIPS is good for supporting 3D prints.

It is a 3D biodegradable material, an amorphous thermoplastic material. It's a type of plastic used in things that don't get too hot. People often use it as a dissolvable support for 3D printing. ABS is another, stronger material that can handle higher temperatures and impacts better than HIPS. It's safe to use, so it won't harm people handling it. Just like PVA, HIPS is good for supporting 3D prints.

HIPS (HIGH IMPACT POLYMER)

PETG (Polyethylene Terephthalate Glycol)

PETG, a copolymer of PET (polyethylene terephthalate) and glycol, combines the strengths of both materials, addressing the overheating problems of PET. ABS is toxic when printed, whereas PETG produces no harmful fumes. Printing with PETG is convenient as it doesn't require ventilation or enclosure. PETG offers greater impact resistance and flexibility than PLA and is easier to print than ABS .

PETG, a copolymer of PET (polyethylene terephthalate) and glycol, combines the strengths of both materials, addressing the overheating problems of PET. ABS is toxic when printed, whereas PETG produces no harmful fumes. Printing with PETG is convenient as it doesn't require ventilation or enclosure. PETG offers greater impact resistance and flexibility than PLA and is easier to print than ABS .

PETG (Polyethylene Terephthalate Glycol)

Nylon (PA) is a synthetic material used in many industries. It's a special kind of plastic that can be turned into fibers, films, and molded parts. People like using it in medical stuff like stitches, catheters, and fake teeth because it works well with the body. Nylon is great because it's strong, flexible, and can resist damage from chemicals and corrosion. This makes it an important type of plastic .

Nylon (PA) is a synthetic material used in many industries. It's a special kind of plastic that can be turned into fibers, films, and molded parts. People like using it in medical stuff like stitches, catheters, and fake teeth because it works well with the body. Nylon is great because it's strong, flexible, and can resist damage from chemicals and corrosion. This makes it an important type of plastic .

PA (Polyamide)

PA (Polyamide)

A new type of plastic, called Carbon Fiber Reinforced PLA, has been created to make strong and lightweight materials for 3D printing . This material is tough, sticks well together in layers, and doesn't bend easily. Compared to other 3D printing materials, Carbon Fiber PLA is very strong but not necessarily more flexible. Its rigidity comes from the added carbon fiber, providing extra support for structures. However, this also makes it a bit less flexible and somewhat more brittle than regular PLA. Despite these differences, Carbon Fiber PLA has similar properties to standard PLA and offers stable printing without warping

A new type of plastic, called Carbon Fiber Reinforced PLA, has been created to make strong and lightweight materials for 3D printing . This material is tough, sticks well together in layers, and doesn't bend easily. Compared to other 3D printing materials, Carbon Fiber PLA is very strong but not necessarily more flexible. Its rigidity comes from the added carbon fiber, providing extra support for structures. However, this also makes it a bit less flexible and somewhat more brittle than regular PLA. Despite these differences, Carbon Fiber PLA has similar properties to standard PLA and offers stable printing without warping

Carbon Fiber

PMMA, approved by the FDA, is a synthetic biomaterial commonly used in making things like dental implants and structures to fix issues in the face and skull. It's also used as bone cement to rebuild lost bone and attach implants. PMMA is a type of plastic known for being the main stuff in acrylic sheets, and that's why it's sometimes called acrylic filament.

PMMA, approved by the FDA, is a synthetic biomaterial commonly used in making things like dental implants and structures to fix issues in the face and skull. It's also used as bone cement to rebuild lost bone and attach implants. PMMA is a type of plastic known for being the main stuff in acrylic sheets, and that's why it's sometimes called acrylic filament.

PMMA: (Polymethyl methacrylate)

Ceramics can break easily (brittle), which is a problem when we need things to be a bit flexible or tough. Making 3D objects with ceramic materials is harder than using regular materials because it requires high temperatures and special tools. Ceramic fibers are important for making new lightweight materials that can handle high temperatures. In the past, people tried to make regular plastic materials better by adding tiny amounts of different powder or fiber materials. They also tried using ceramic fillers to improve the strength or heat resistance of plastics or for uses in biology.

Ceramics can break easily (brittle), which is a problem when we need things to be a bit flexible or tough. Making 3D objects with ceramic materials is harder than using regular materials because it requires high temperatures and special tools. Ceramic fibers are important for making new lightweight materials that can handle high temperatures. In the past, people tried to make regular plastic materials better by adding tiny amounts of different powder or fiber materials. They also tried using ceramic fillers to improve the strength or heat resistance of plastics or for uses in biology.

Ceramic

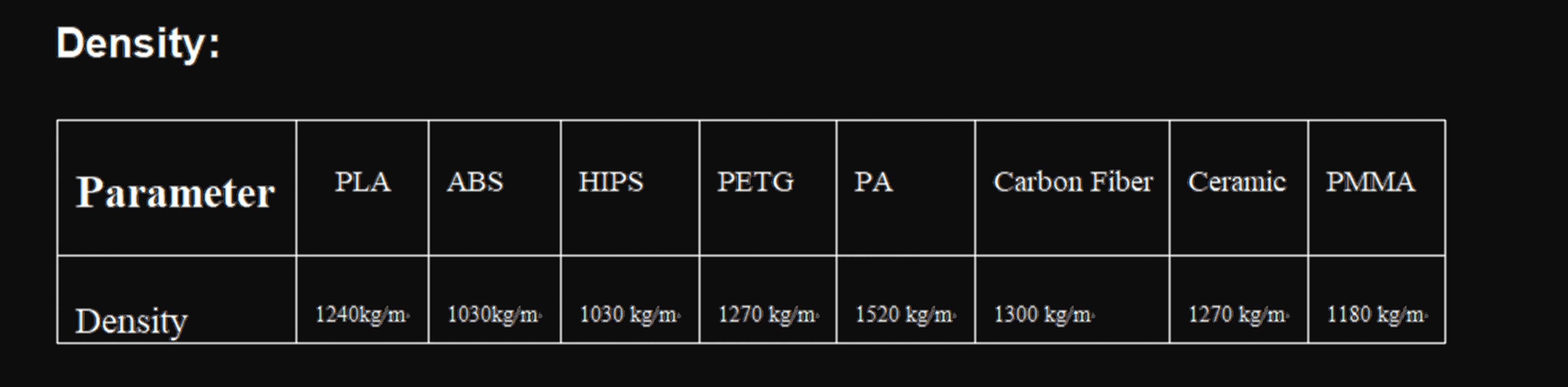

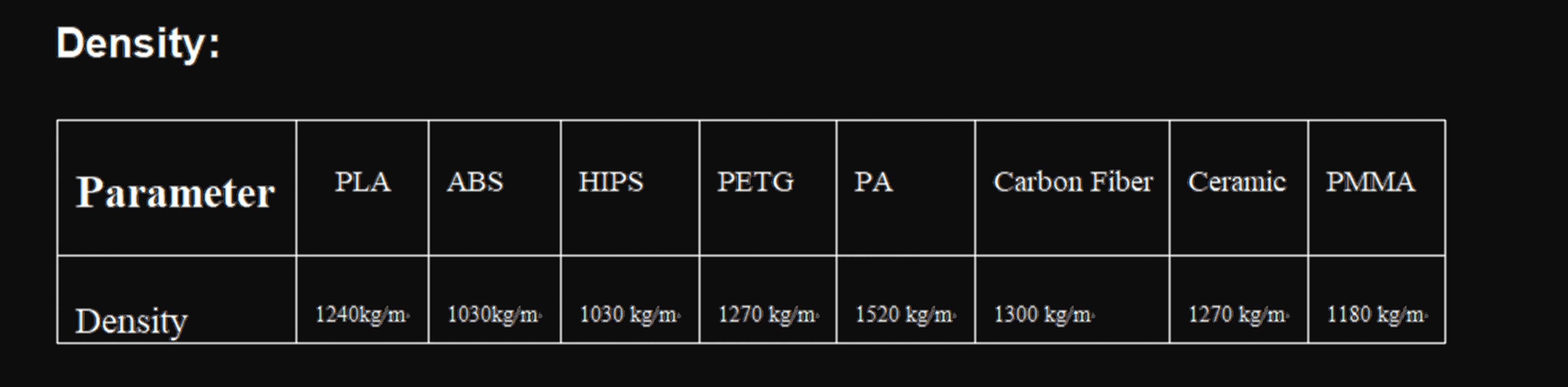

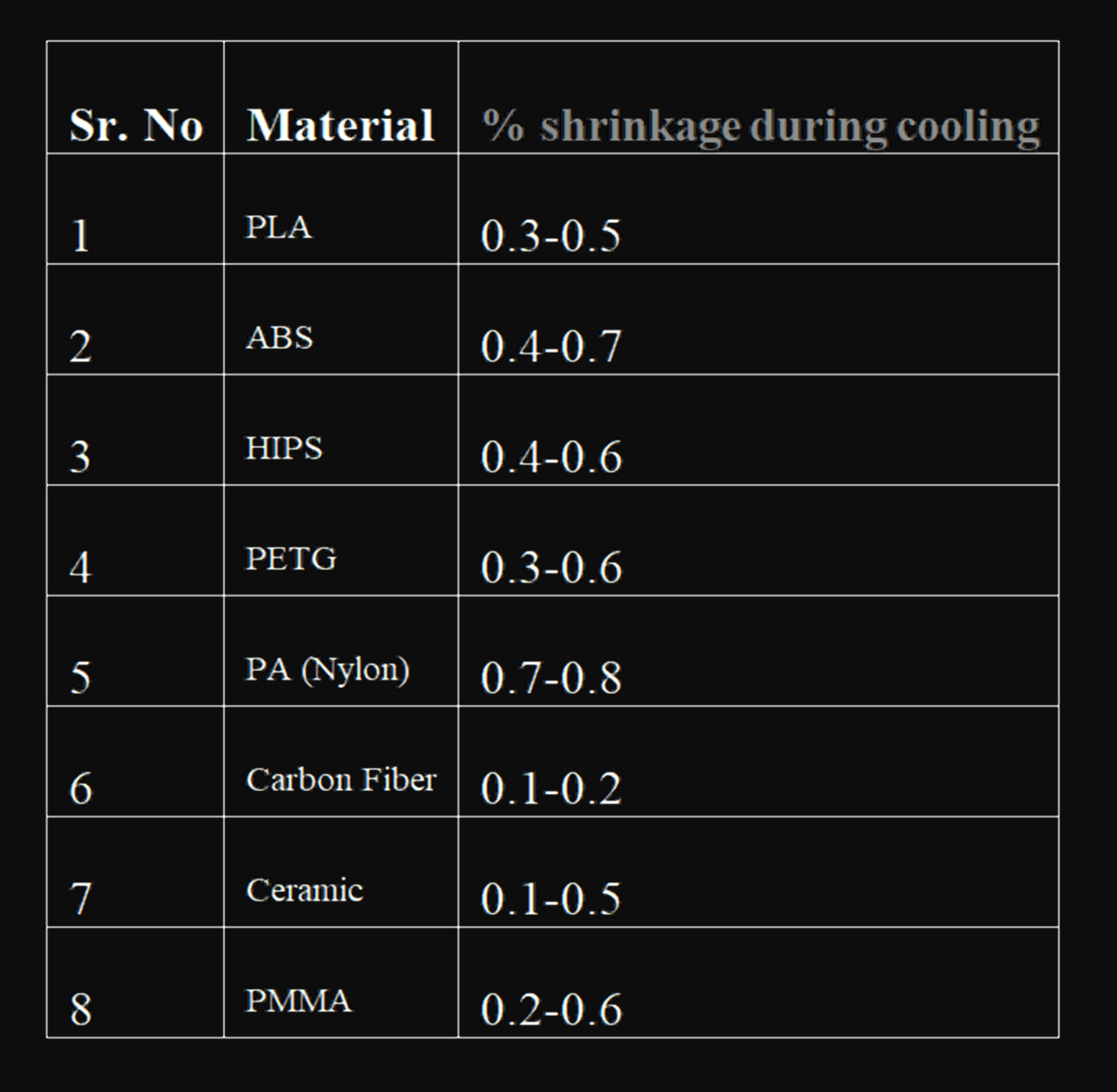

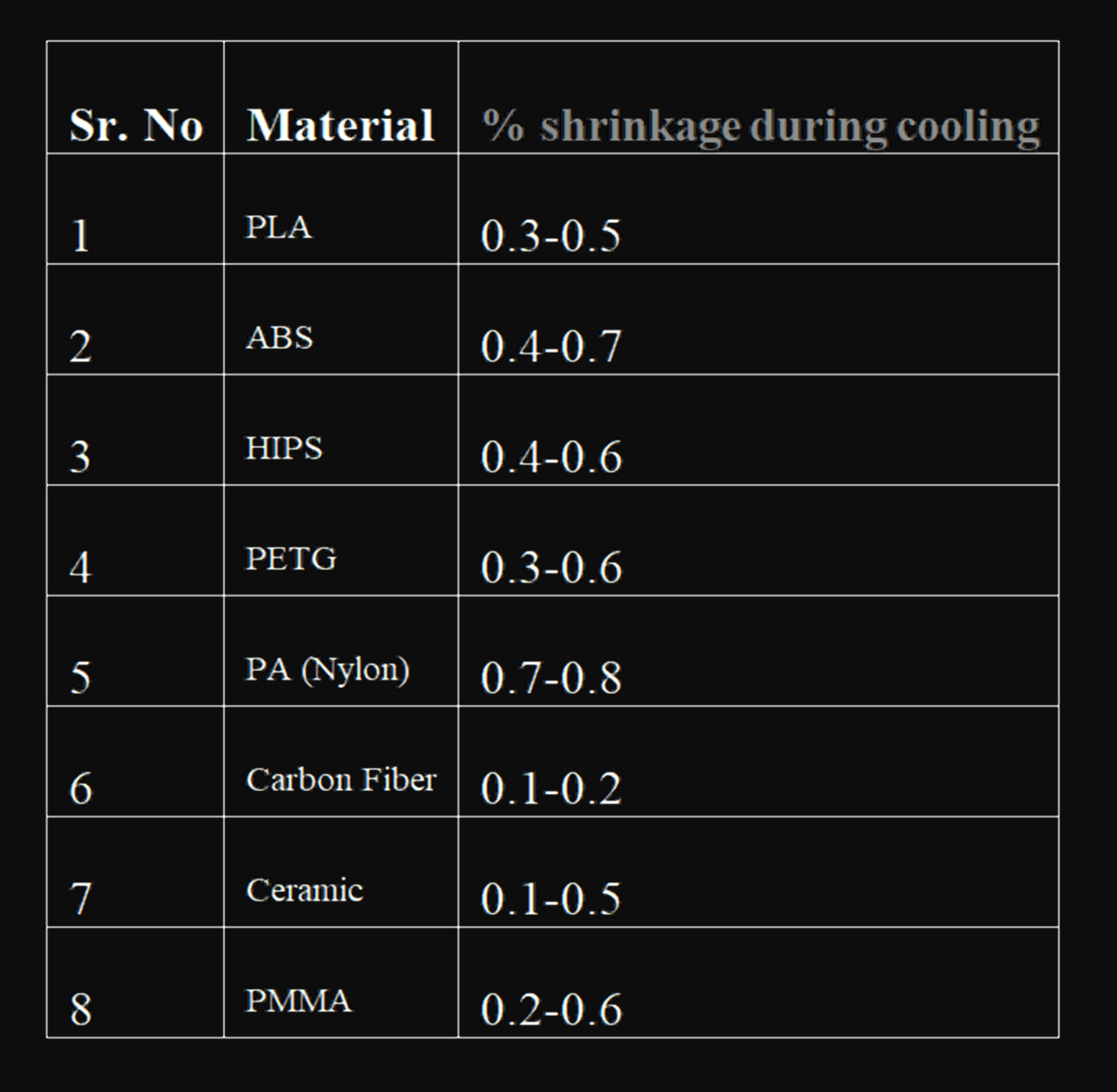

Shrinkage values :

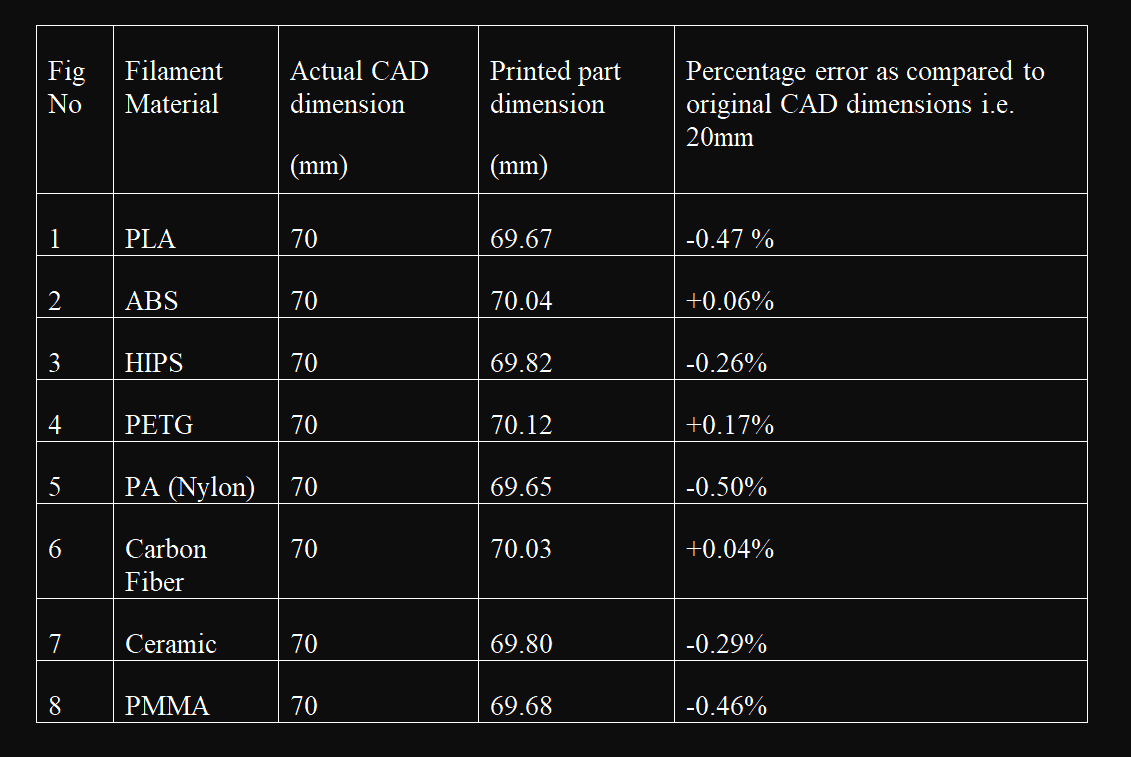

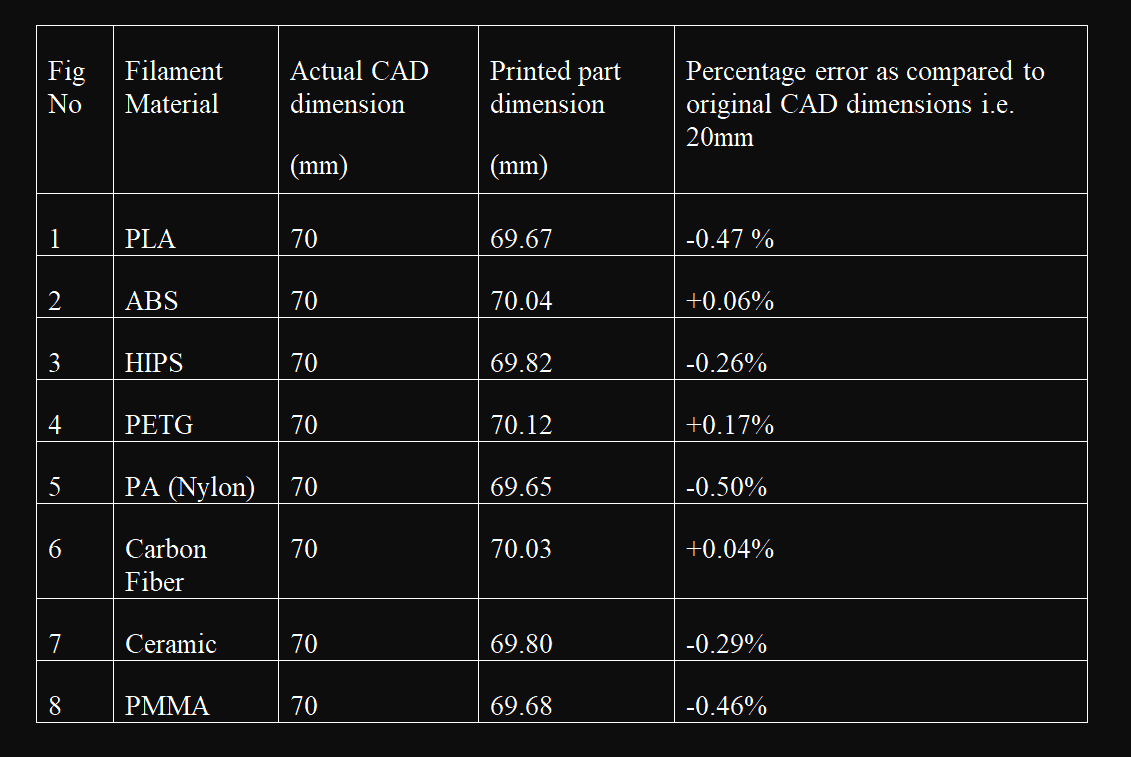

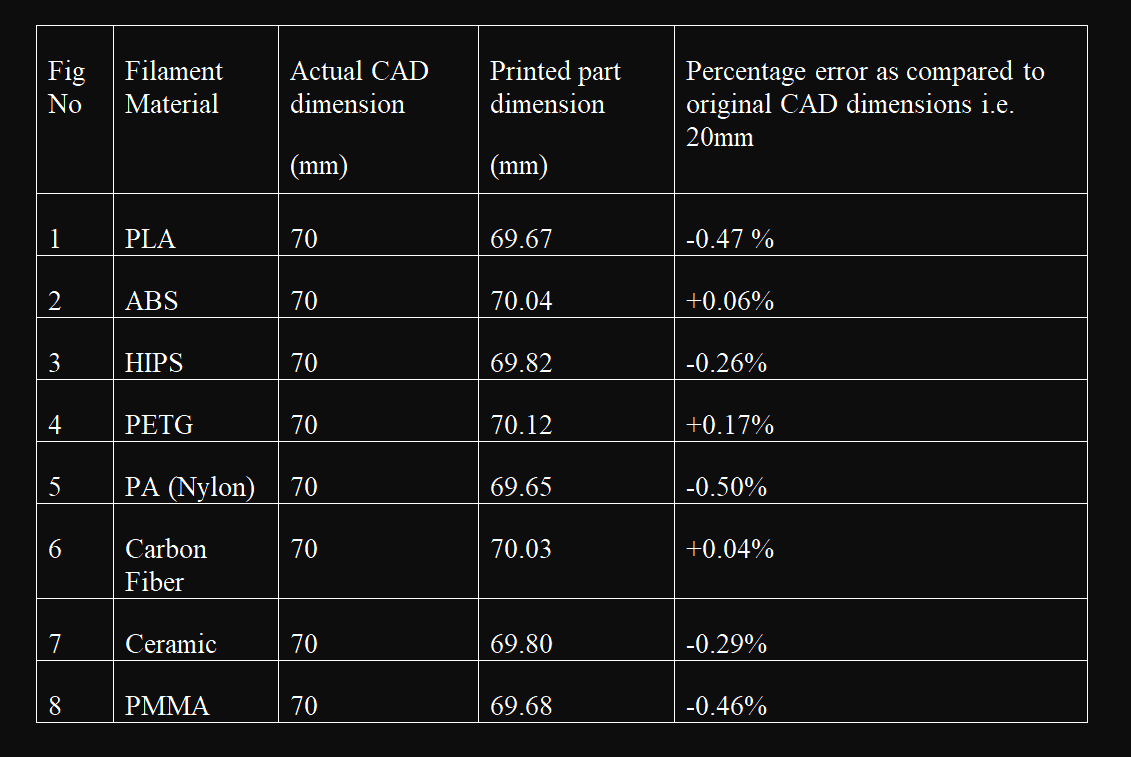

Percentage error in dimensions :

The negative percentage indicates that the size of the printed model was smaller than its actual dimensions. On the other hand, positive percentages mean the model's overall size increased by the respective percentage. The variations in these values are caused by factors like shrinkage (refer to Table 4), influenced by printing temperature, layer height, and the speed of the cooling fan within the printer. For PLA, the dimension turned out to be 69.67 mm, with a shrinkage of 0.3-0.5%. Our results show a percentage error of -0.47%, which falls within the expected shrinkage range (0.3-0.5%).

Among the nine materials tested, three (ABS, PETG, and Carbon Fiber) exhibited positive deviations (Figure 9). The analysis highlights that PETG had the maximum error with a positive deviation of +0.17%, while PA(Nylon) had the least error with a negative deviation of -0.50%. Importantly, the overall percentage error in dimensions did not exceed ±0.5%.

The negative percentage indicates that the size of the printed model was smaller than its actual dimensions. On the other hand, positive percentages mean the model's overall size increased by the respective percentage. The variations in these values are caused by factors like shrinkage (refer to Table 4), influenced by printing temperature, layer height, and the speed of the cooling fan within the printer. For PLA, the dimension turned out to be 69.67 mm, with a shrinkage of 0.3-0.5%. Our results show a percentage error of -0.47%, which falls within the expected shrinkage range (0.3-0.5%).

Among the nine materials tested, three (ABS, PETG, and Carbon Fiber) exhibited positive deviations (Figure 9). The analysis highlights that PETG had the maximum error with a positive deviation of +0.17%, while PA(Nylon) had the least error with a negative deviation of -0.50%. Importantly, the overall percentage error in dimensions did not exceed ±0.5%.